Sparks

Clock Repair

(203)-214-4625

We make house calls

for grandfather clocks

Wear and Restoration

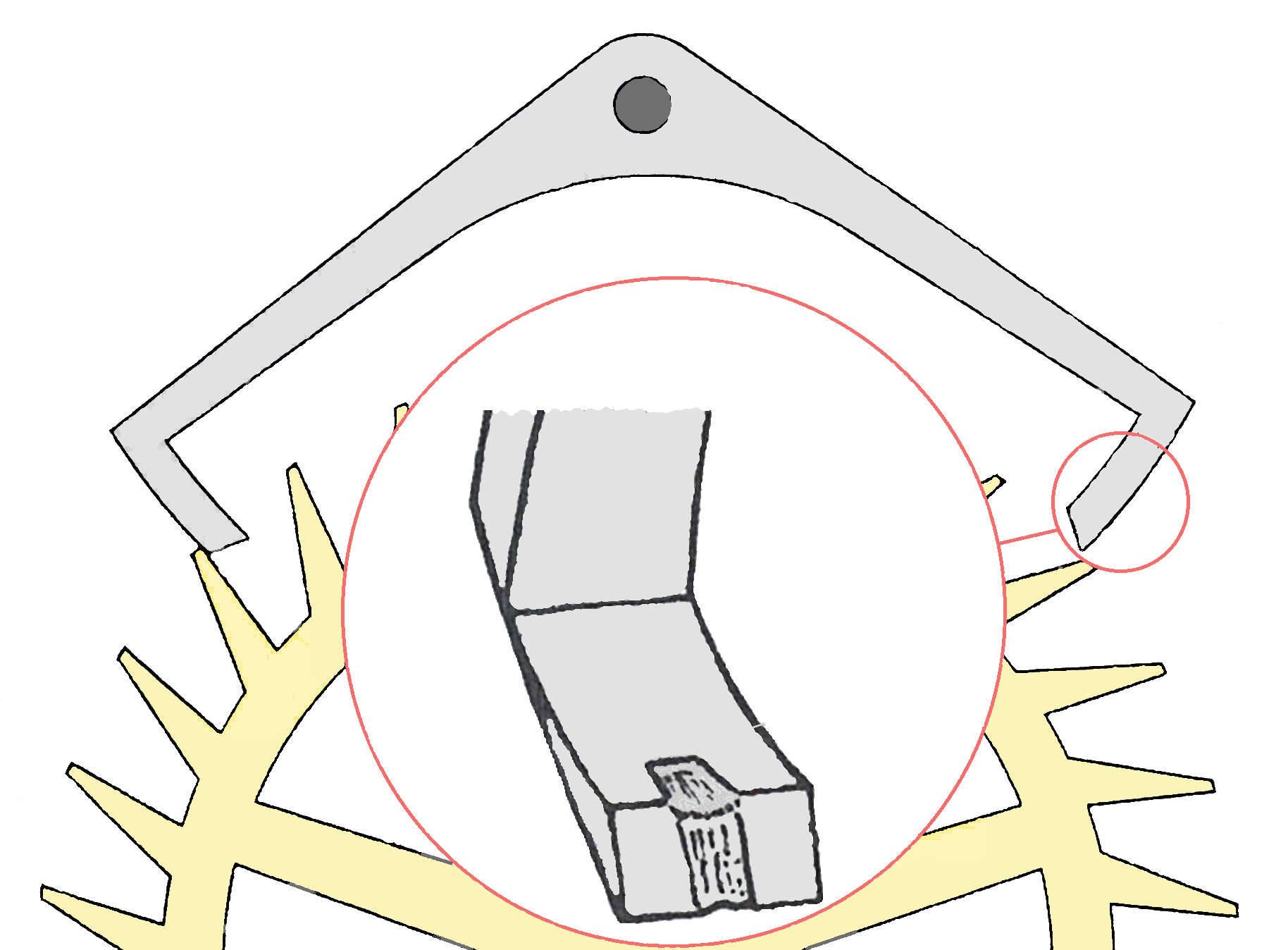

The pivot holes will wear because they have steel pivots working in them.

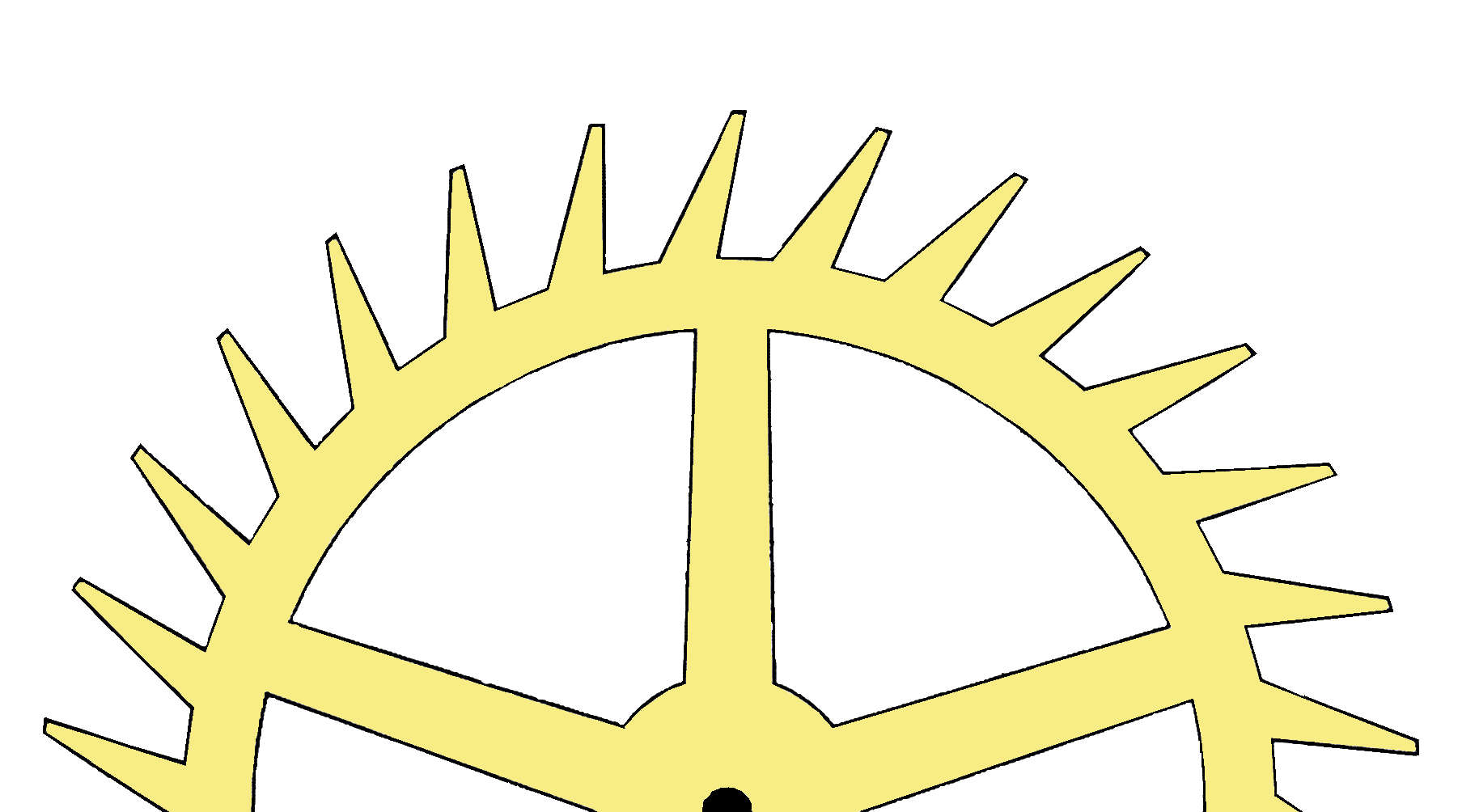

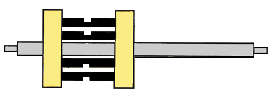

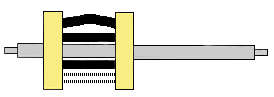

Here we can see a good unworn hole on the left, but on the right the pivot has worn itself a pocket in the side of the hole. This not only increases the friction of the pivot, but also affects the gear train itself.

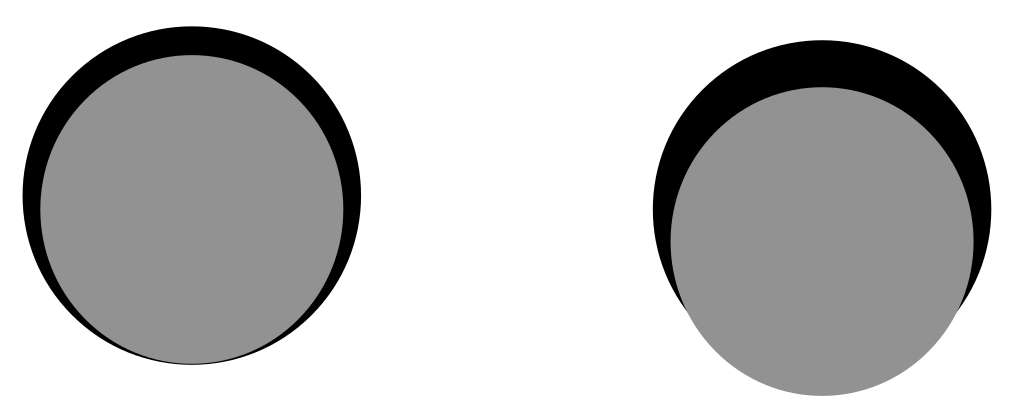

When we add center lines indicating the original placement of the pivot it can be seen how far it becomes misplaced. This reduces the distance between the arbors and instead of the gear teeth meshing properly they bind together.

Worn pivot holes need to be restored by installing a bushing, which will create a pivot hole with new metal.

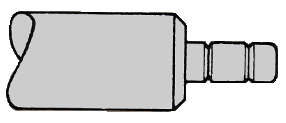

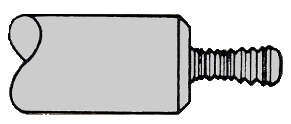

Pivots will also wear, and this speeds up the pivot hole wearing out.

Some can be restored and polished.

But others are so worn out that they need to be replaced by drilling a hole precisely in the center of the arbor and installing a new steel pivot.

The pallets power the pendulum. Over time a groove will be worn into the steel. This can sometimes be polished out, but if it is worn too much the geometry of the escapement will be changed, and the pallets need to be restored or replaced.

Sometimes the teeth will wear on the working surface and become cupped. This happens when a spring that is too powerful was used as a replacement. The original spring either broke or was just too old to provide the power it once did. The steel used in springs today is much better, and stronger than years ago and if the same size is used as a replacement it will be too strong (an old spring with a thickness of .018 should be replaced with one .0165). Once this type of wear occures the gear has to be removed, turned around, and remounted onto it's arbor so we are using unworn metal as the working surface.

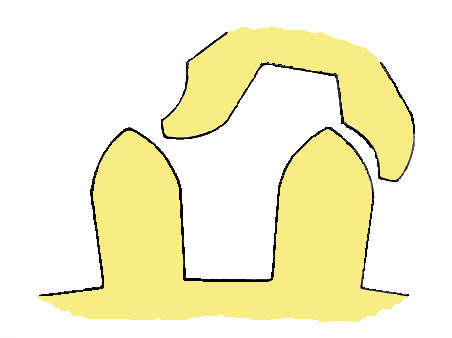

The trundles in a lantern pinion can over time have a groove worn into them.

Or, sometimes when a spring breaks they can be bent, or missing. Either way they need to be replaced.